0191 5166636

enquiries@ht-uk.com

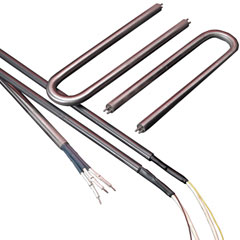

The MULTICOIL heater tubular element with multiple coils and/or thermocouples inside one sheath answers the need for a versatile, innovative tubular multiple coil heater. Watlow's patented method of packaging a thermocouple inside of a heater with one or more resistance coils, gives the ability to sense a heater's internal temperature accurately, every time.

Moreover, this is the first tubular heater in the industry with three-phase capability. The three coil, three-phase heater will offer a compact package solution while delivering the full power required in a compact heater package. Previously three separate heaters would have been required to do the same job; therefore Watlow's MULTICOIL™ heater capabilities save money.

Specifications:

| Material | Maximum Operating Temperatures | Maximum Watt Densities | ||

|---|---|---|---|---|

| °F | °C | W/in2 | W/cm2 | |

| Alloy 800 | 1400 | 760 | 45 | 6.9 |

| 304 stainless steel | 1200 | 650 | 45 | 6.9 |

| 316 stainless steel | 1200 | 650 | 45 | 6.9 |

- Watt densities to 60 W/in² (9.3 W/cm²)

- Alloy 800 sheath temperatures to 1200°F (650°C)

- 304 and 316 stainless steel sheath temperatures to 1200°F (650°C)

Applications:

- Foodservice

- Process

- Medical

- Milled groove

- Plastics

- Plating

- Oven heating

- Semiconductor

Features & Benefits:

| Features | Benefits |

|---|---|

| Three-phase capability |

|

| Single-ended |

|

| Multiple coil operations |

|

| Versatile forming capabilities |

|

| Internal construction with sensor |

|